Nearly 18 years ago the first Nissan Qashqai rolled off the production line in Sunderland, UK, creating the crossover segment and sending shockwaves around the automotive world.

Fast forward to 2024, and with more than four million customers in more than 100 countries, the fastest-selling car ever in the UK car industry has been upgraded once more - with a bold design and significant technology updates to enhance the customer experience.

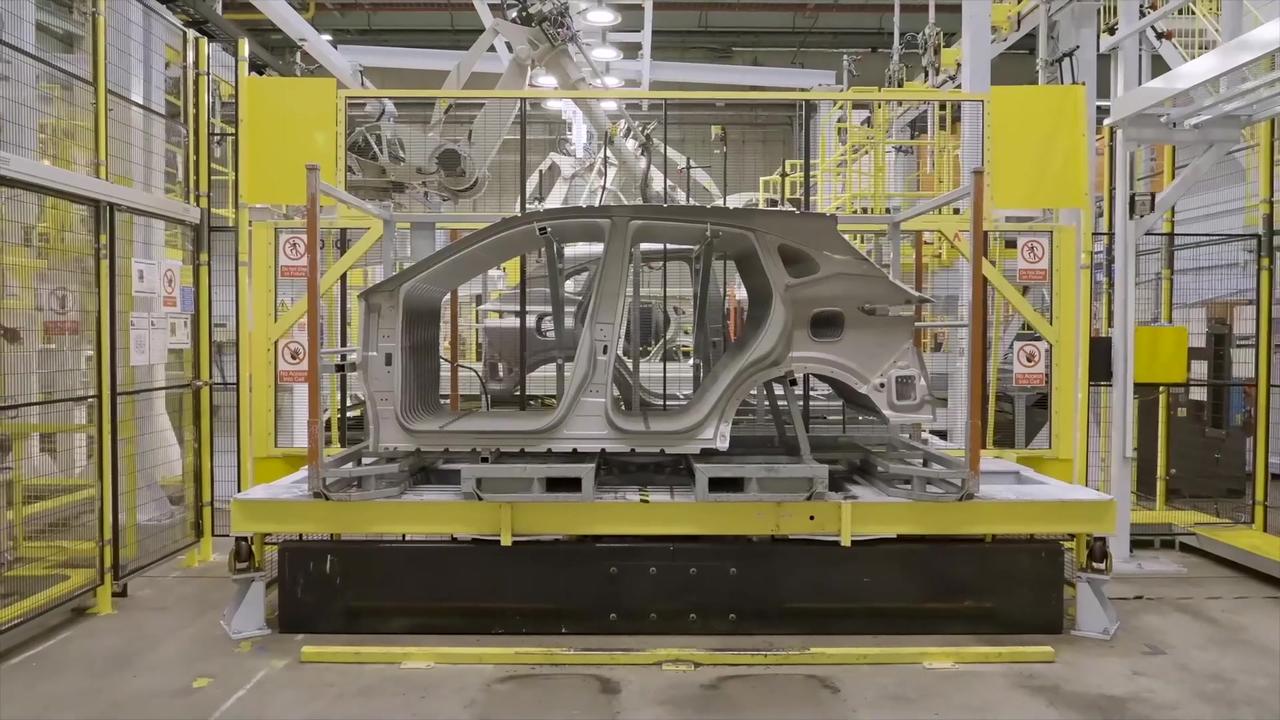

The new Qashqai, electrified with Nissan's unique e-POWER system, is now in production at its home in Sunderland ahead of its arrival in the coming weeks to Nissan dealers across Europe and beyond.

The latest upgrades required a fresh £30m investment in the plant, building on Nissan's total investment in the UK of £6bn.

The refreshed Qashqai arrives as Nissan continues to develop its EV36Zero vision in Sunderland, a blueprint for the future of automotive manufacturing, bringing together electric vehicle manufacturing and battery production, powered by renewables.

Adam Pennick, Nissan's Vice President for Manufacturing in the UK, said: "We're so proud to call Sunderland plant the home of the Qashqai.

Having the number one team behind the number one crossover is a winning formula, and we can't wait to see how much our customers enjoy the new design and extra tech." Designed, engineered and built in Britain, the first Qashqai was produced in Sunderland towards the end of 2006, ahead of its launch in 2007.

Its instant popularity saw production in Sunderland reach record levels, with the plant recording the highest annual volumes in the history of the UK car industry, and Qashqai becoming the fastest UK-built car to achieve 1 million, 2 million, 3 million and then 4 million production units, spawning more than 20 competitors in the process.

Sunderland Plant is also home to the Nissan JUKE and all-electric Nissan LEAF, where production supports 7,000 jobs in Nissan's UK teams. That includes Nissan's Design Centre in Paddington, London, the Technical Centre in Cranfield, Bedfordshire, the manufacturing team in Sunderland, parts centre in Lutterworth and sales and marketing team in Rickmansworth, as well as a further 30,000 jobs in the UK supply chain.